Chemical Plant

– the chemical plant is the heart of our business

– the chemical plant is the heart of our business

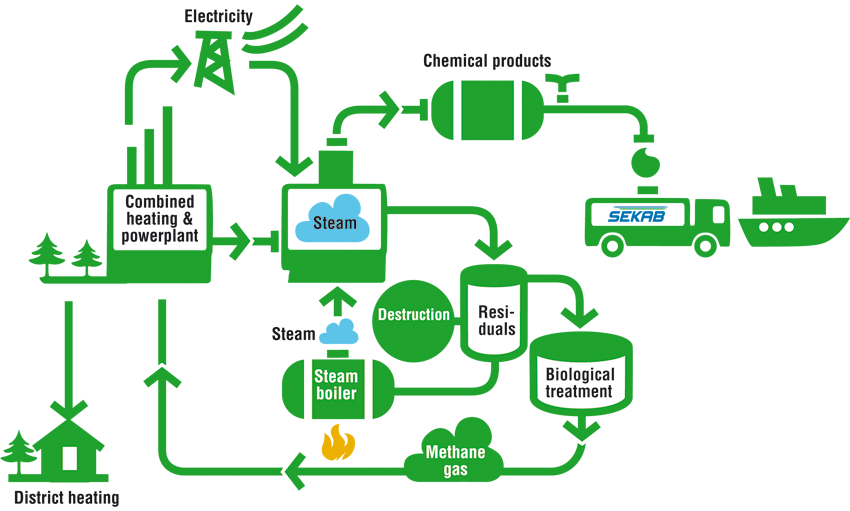

In Sekab’s chemical plant, we produce acetaldehyde, ethyl acetate and acetic acid. We refine and convert ethanol into biofuels and ethanol-based chemical products. We work in catalytic processes in which the ethanol raw materials react highly effectively, the largest by-product being ordinary water.

Sekab has very advanced gas purification in its production lines. The outgoing process water is treated in an anaerobic (oxygen-free) water purification process which is highly efficient – after purification, the water has a status that is close to completely unaffected natural water.

In the chemical plant we produce Acetaldehyde, Ethyl Acetate and Acetic Acid from ethanol raw materials. The ethanol is biological and fossil-free.

In our chemical plant, we produce green products from renewable raw materials in a process that is run on green bioenergy. This provides a product with very low emissions of climate impacting carbon dioxide with respect to the entire chain.

SEKAB can also supply products manufactured from second-generation cellulosic ethanol as the raw material. In this way, we keep processes and products as climate neutral as is at all possible.

We refine ethanol into biofuels and chemicals. We develop biorefinery technology for new sustainable product possibilities based on cellulose raw materials.