96 percent of everything that is manufactured needs chemicals. They are found in all everyday products around us from the paint on the wall, to our clothes and children’s toys. The absolute majority of the chemicals used globally today are made from fossil raw materials. Sekab offers the chemical industry green alternatives on the way to an absolutely necessary transition. Our chemicals are building blocks needed to manufacture sustainable end products such as lacquers, paints, glues, plastics, cosmetics, pharmaceuticals, cleaning products and packaging.

Sekab is a green chemical company and a part of High Coast Innovation Park in Domsjö, outside of Örnsköldsvik. Our research and development are prominent, and at the same time, we are taking our knowledge all the way to finished products and methods.

Sekab’s biobased chemicals help our customers phase out unsustainable products and processes. We are part of a green industrial revolution that is fundamentally changing how we produce goods and services. We create value for owners, employees, customers, and society by driving development towards a sustainable society and increasing the use of renewable raw materials and sustainable products.

We are a part of the Science Based Targets initiative, a global body that offers a methodology and framework that guides companies to set science-based emissions targets to contribute to limited global warming in line with the goals of the Paris Agreement. The initiative is a collaboration between the UN’s Global Compact, CDP, the World Resources Institute and the World Wide Fund for Nature.

Sekab is a chemical company with a full focus on sustainable business – both literally and figuratively. With over a hundred years of experience and ambitions as an active challenger, we are an important part of the necessary transformation in the industry.

In our production facility at the High Coast Innovation Park in Örnsköldsvik, we refine and convert large quantities of bioethanol into chemical products such as acetaldehyde, ethyl acetate, acetic acid, and various blending products every week. We usually deliver in bulk volumes.

Our chemicals are green building blocks used in a range of industrial processes and products. Paints, pharmaceuticals, perfumes, cleaning products, windshield washer fluid, varnishes, and inks are some examples of the end result of our chemicals.

Our research and development is outstanding. In that work, the demonstration facility Biorefinery Demo Plant is a unique and important asset, as is our investment in developing technology that makes it possible to produce ethanol from forest residues.

Business model

Sekab’s bio-based chemicals and fuels help our customers phase out unsustainable products and processes. We are a part of a green industrial revolution that is fundamentally changing how we produce goods and services.

We create value for owners, employees, customers and society by driving the development toward a sustainable society and increasing the use of renewable raw materials and sustainable products.

How we work

At the end of 2021, we adopted the strategic platform HELA Sekab. In 2022, this has been implemented and taken further.

A successful Sekab rests on four cornerstones:

Sustainability should extend through all of Sekab’s activities. Our ambition is to be the world’s greenest chemical company. Our view on sustainability is based on the UN’s global goals in Agenda 2030. Sekab’s bio-based products contribute to a more sustainable world and reduced greenhouse gas emissions. Sekab should also work for social sustainability by being a good employer and a responsible and present actor in our local community.

Sekab is a company with endless possibilities but limited resources. It is therefore important that Sekab does its utmost to constantly prioritize what is most important and be as efficient as possible in our tasks. One way to achieve this is to constantly challenge ourselves and our work methods.

Sekab operates in a highly competitive market. To prepare Sekab for the future, the company’s profitability is a fundamental factor. Profitability provides opportunities for development, investments and to move forward, while our owners receive a return on their investment.

Sekab’s most important asset is our employees. Sekab should therefore be an attractive employer and partner for our customers and other stakeholders. Sekab’s attractiveness is based on successful collaborations and a strong value base, built on commitment, trust and creativity.

In 2023, work with HELA Sekab will continue. We are updating our goal documents and key figures. All activities, business

and processes will be permeated by our four cornerstones:

Sustainability | Efficiency | Profitability | Attractiveness

Our values are an incredibly important part of the HELA Sekab aspect of attractiveness. They help us gather around, live and realize our vision. Three selected characteristics which permeate our actions, our hiring process and our interactions are: Commitment, creativity and trust.

Sekab’s employees are committed

Sekab’s employees are creative

Sekab’s employees have trust

How we work

Sustainability is not just a part of our company, it is the core of our entire business. Our sustainability work is based on the UN’s global goals in Agenda 2030. These goals help us sort out the sustainability aspects of our operations and take an even better comprehensive approach. In our sustainability report, the global goals provide structure by linking the seven selected goals where we can make the biggest difference to our four focus areas.

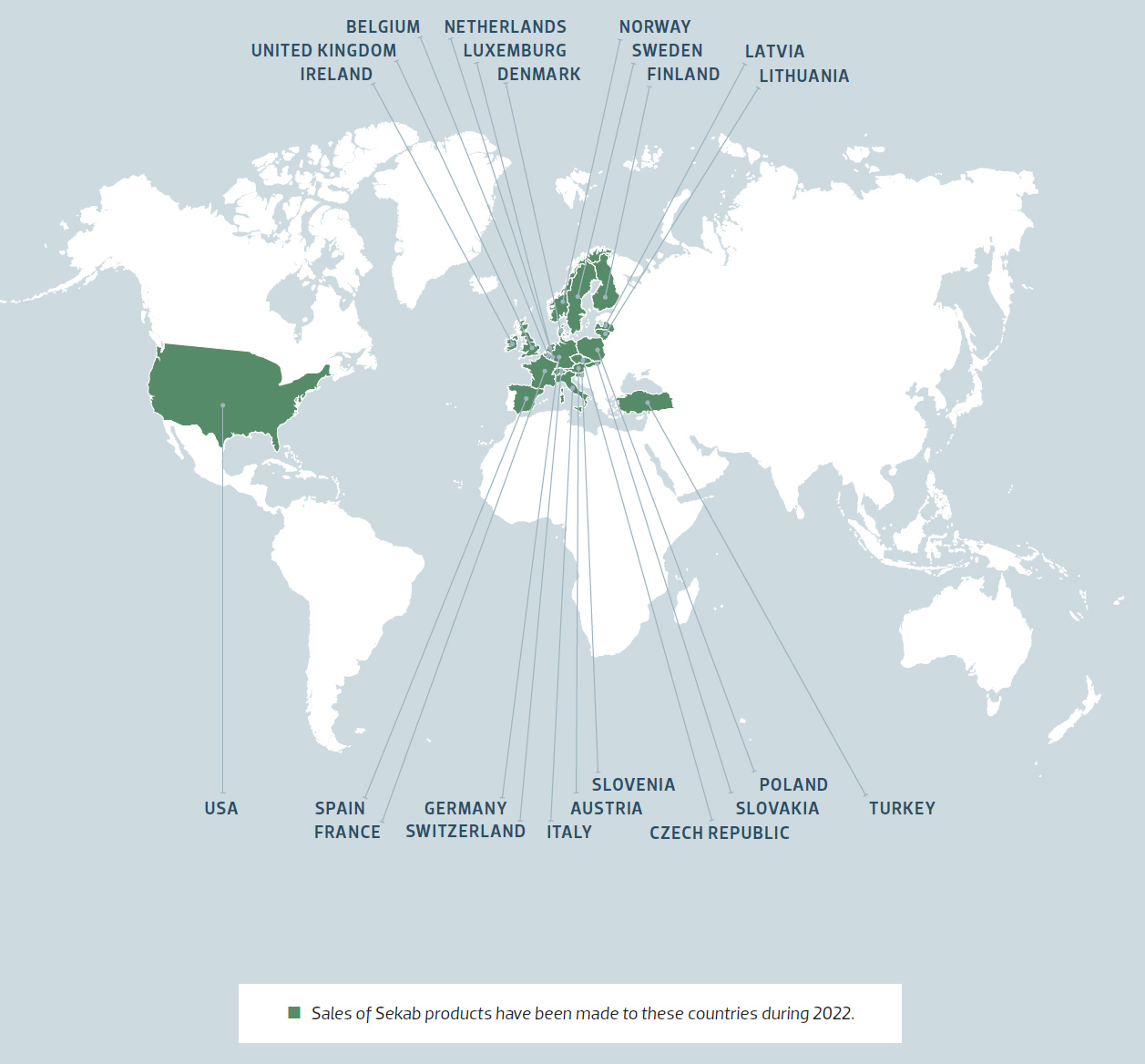

Our green chemicals are produced and sold from our facility in Örnsköldsvik. We manage our operations with the support of the environmental standard ISO 14001 and the quality standard ISO 9001. These help us both in our internal work and in describing our offering to external parties.

In 2022, Sekab joined the globally leading evaluation system EcoVadis. In our first year, we were awarded the gold status, which only five percent of all member companies achieve. Work has started during the year to connect to further independent systems, such as the Science Based Target Initiative.

Our certifications and ambitions are realized in a number of controlled documents, where the corporate-wide environmental, safety, and occupational health policy is the primary one.

Sekab also operates according to the environmental standard ISO 14001 and the quality standard ISO 9001.

A materiality analysis has helped us to map the most important issues for the company and stakeholders in terms of sustainability. The analysis included both internal and external stakeholders (board/owners, employees, customers and suppliers) and the results of the analysis laid the foundation for developing Sekab’s sustainability report.

For a supplier in the industrial value chain, it is crucial to be a reliable partner. Therefore, our structured work with analyzing and managing risks is a prioritized issue in our operations.

An important part of business management is to continuously analyze and manage the risks that may have a negative impact on Sekab. A good understanding of the risks and monitoring changes in the risk profile provides the basis for informed decisions. These decisions, in turn, contribute to creating opportunities and fulfilling the company’s strategic goals.

To ensure a good overview of the risks that our operations are exposed to, we work systematically to identify, analyze, assess, and manage risks. In addition, risk analyses are carried out continuously in connection with projects, investments, and changes in operations. The annual strategic risk process results in a number of identified risks with different priorities.

Financial risks have a potential impact on Sekab’s results and financial position. We may be exposed to interest rate risk, currency risk, credit risk, financing risk, and liquidity risk.

Operational risks can be directly related to Sekab’s business activities with potential impact on sustainability, results, and financial position.

Strategic risks can have long-term consequences for Sekab’s business activities. They may involve global changes with potentially significant effects on us at multiple levels.

Our sustainability-related risks are mainly operational and closely linked to our focus areas. Following is a report on these risks:

IT risks

A functioning, secure and well-protected IT environment is essential to Sekab’s operations. Identified risk areas include IT attacks and insufficient maintenance that could result in direct disruptions to our operations. We therefore carry out systematic IT security work, which includes identifying IT risks, monitoring the environment and conducting ongoing maintenance. Focus area: Responsible business

Health and safety risks

Sekab’s operations involve handling large quantities of flammable materials. An accident in the chemical plant could cause serious harm to people, the environment and property. Legally, a serious occupational health and safety accident could result in fines or other legal sanctions. To prevent incidents and accidents in the workplace, Sekab systematically works on occupational health, safety and fire protection issues. Focus area: Employees

Environmental risks

Sekab’s operations involve handling large quantities of chemicals. A major release could affect the local environment and lead to legal sanctions, as well as damage to our trademark. Consideration for the external environment is always a high priority in Sekab’s operations. As part of our environmental work, we continually monitor and evaluate our operations from an environmental perspective to prevent unintentional releases. Focus area: Climate and energy

Regulatory Risks

Laws, regulations, and policies for ethanol, fuel, and chemicals can affect production conditions and profitability. Therefore, active monitoring of changes and adjustments to our operations is important. By actively participating in debates and decision-making groups, Sekab can promote favorable conditions for bio-based chemicals and fuels. Focus Area: Social Responsibility

Infrastructure Risks

Sekab’s products are primarily delivered by sea and rail transport. Secure deliveries on time are a high priority for our customers. By having the option to deliver via different modes of transportation, we make ourselves less dependent on one type of traffic. Furthermore, we actively work to participate in forums, inform, and engage in dialogue with decision-makers to ensure that infrastructure issues related to our operations are given high priority in society. Focus Area: Responsible Business

Ethical Risks

Ethical risks may arise when Sekab’s employees do not act in accordance with the company’s code of conduct. Risks may also be associated with ethical violations in the supply chain. This can result in fines, legal sanctions, and damage to the company’s trademark. Good business ethics and transparency should extend through everything we do. A clear code of conduct and continuous supplier checks prevent ethical risks. Focus Area: Responsible Business

Risks related to suppliers

If suppliers act in violation of applicable laws, conventions, and agreed-upon conditions, this can lead to quality issues, delivery delays, and production interruptions, which can have a negative impact on Sekab’s profitability and trademark. Sekab’s environmental and code of conduct is always communicated to the supplier, clarifying our expectations. Through supplier assessments, we obtain a qualitative assessment of our major suppliers. Focus area: Responsible business

Competency risks

Attracting, recruiting, retaining, and developing employees is crucial for competitiveness in both the short and long term. We encourage competence development and ensure that the company has the right competencies through strategic work with competence supply plans. Focus area: Employees