Many companies would benefit greatly from finding new efficient ways to clean reactors where biomass is pretreated. At Sekab, a project is well underway to discover new solutions, in a fruitful collaboration between Sekab and Umeå University.

Sekab has a long history of welcoming students and researchers who want to conduct applied studies in the industry. Adnan Cavka is responsible for research and development at Sekab E-Technology and started his own career in the company during his studies. He was an industrial doctoral student at Sekab, before he was hired in 2017.

– I would not call it a tradition, but it has become a strategic habit. It is good for us to collaborate with the academic community, meet new talents and gain access to the infrastructure and competence that exists at Umeå University, says Adnan.

For Johanna Wuotila, who is studying for a master’s degree program in bioresource engineering at Umeå University, it was an easy choice to apply to Sekab for a degree project.

– Sekab and their production are completely in line with my education where we have green process chemistry and biomass processing as a common theme. Now I get to try to implement what I have learned, and at the same time present a challenging issue to the industry in an area that is highly relevant to them, says Johanna.

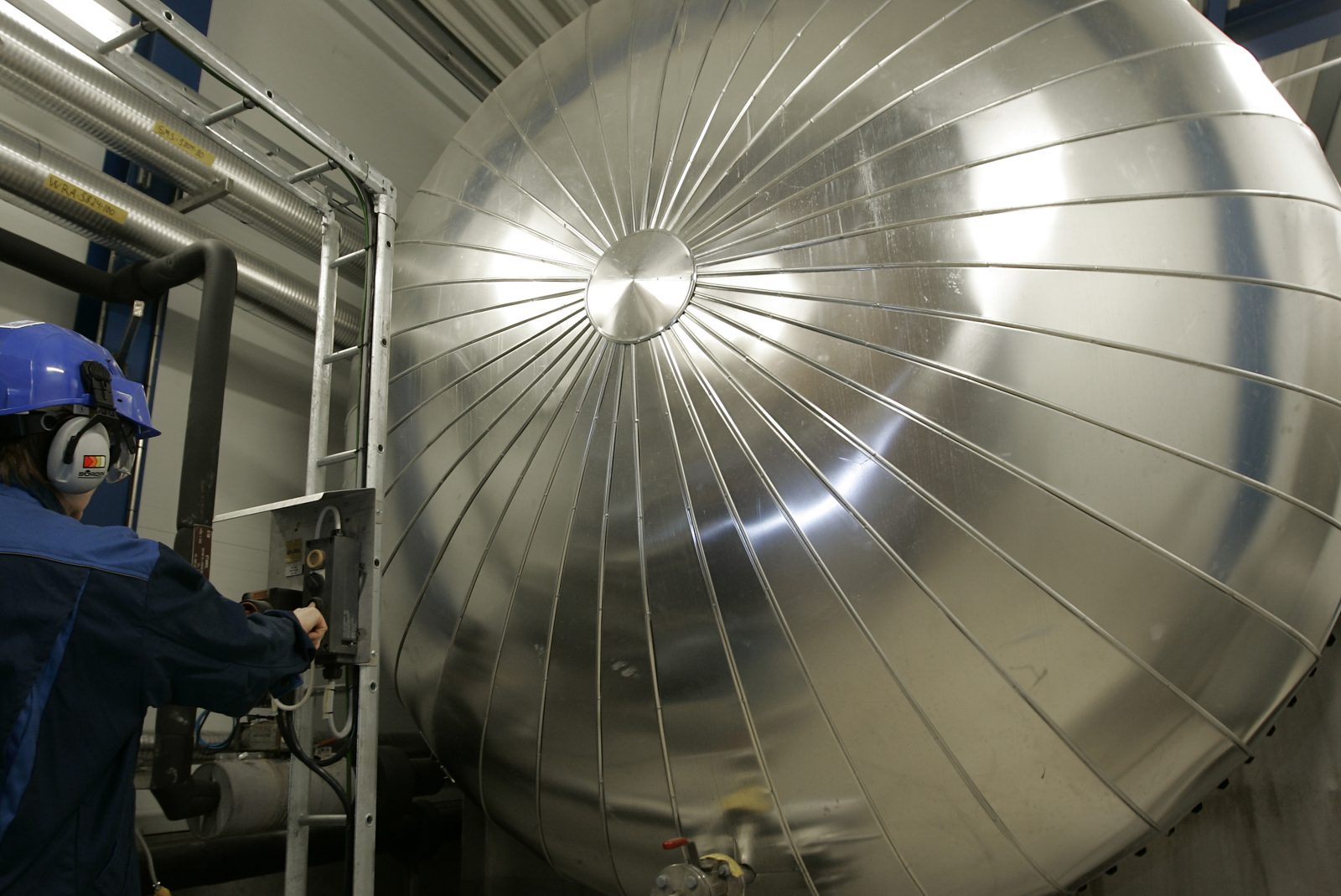

Johanna’s thesis is about the coating that arises in a reactor when you pretreat softwood with sulfur dioxide. The pretreatment is the first important step in Sekab’s process for extracting sugar and lignin from forest industry residues. The problem is that the material is very challenging for the reactor.

– When a coating builds up, it is difficult and expensive to remove mechanically. You must stop the production, take apart and scrape the reactor clean. I am studying what this coating consists of over time to create a routine for how and when you can effectively get rid of the coating, says Johanna.

Adnan Cavka says that this is an issue that many companies have struggled with for a long time.

– Most reactors like this work far below their capacity. If you can find a way to clean without having to stop the process completely, it would create big benefits, he says.

Supervising the work at Umeå University is Professor Leif Jönsson. He is very positive about Johanna’s master thesis at Sekab.

– It is gratifying when students find master thesis projects that fit so well with their education. It is extra interesting that this concerns a new type of industrial process for refining renewable raw materials and that it may become part of the basis for new investments in Swedish business, says Leif.

Johanna Wuotila has only worked for a couple of weeks but has already reported positive findings. The master thesis is due to be submitted by summer.

– I hope it contributes to increased knowledge about these coatings and that it can be a valuable foundation in future handling of reactors, says Johanna.