Every day, we at Sekab work with solutions and products that will help make a move from fossil to circular and sustainable society a reality. That is why it is extra fun and exciting that we now continue and enhance important work together with Praj Industries Ltd.

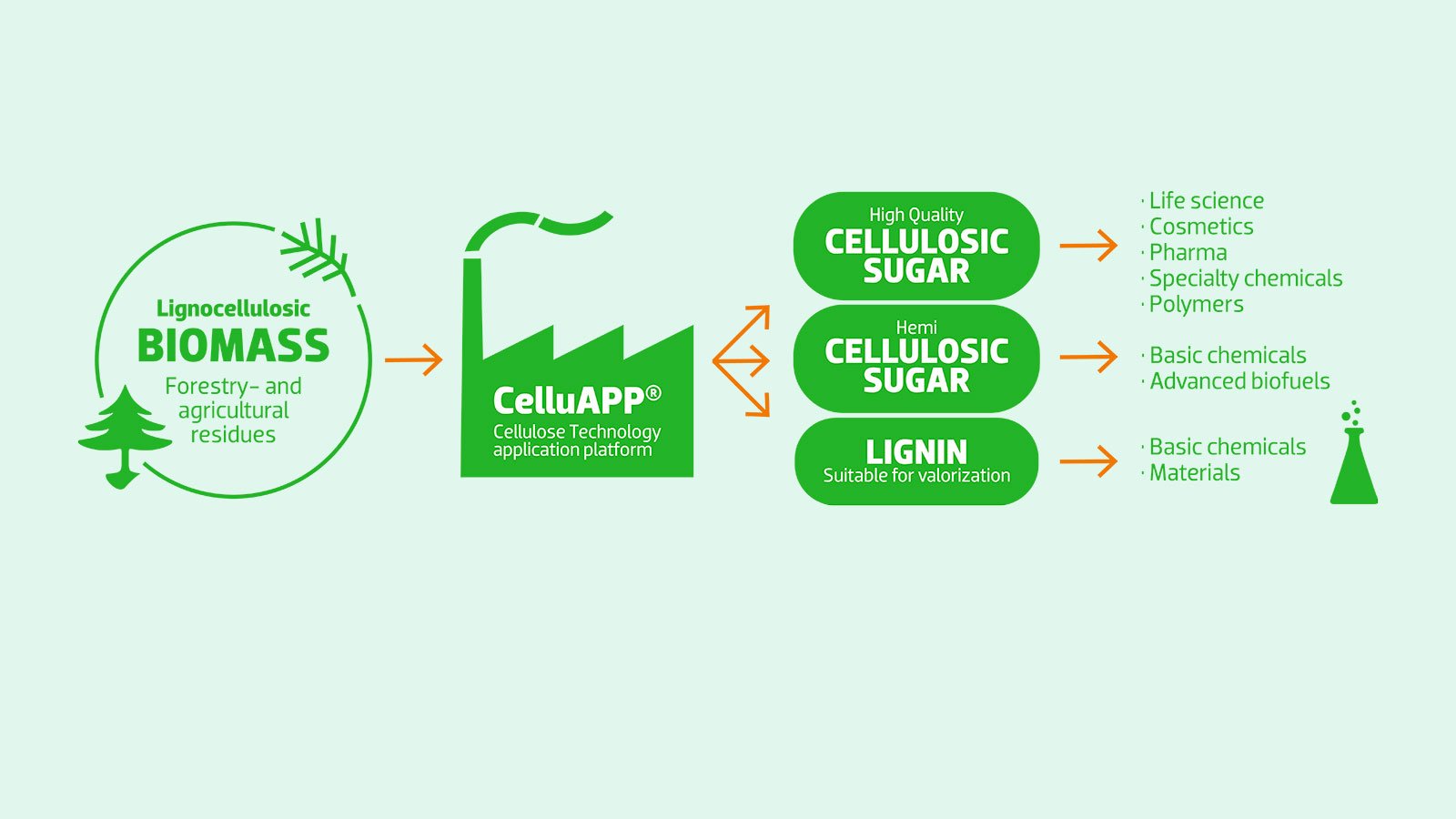

Sekab has since the inauguration in 2004 worked with the development of CelluAPP, in the Biroefinery Demoplant at Örnsköldsvik. CelluAPP is a technology platform for processing cellulose-based biomass.

The plant has a capacity of 2 tonnes of dry biomass per day. A variety of biomass raw materials such as maize residues, wheat straw, grass, other agricultural residues, and eucalyptus to name a few have been processed over the years. Forest remains and mainly coniferous wood such as spruce and pine is the premier feedstock at present. These are raw materials that are available locally.

The years of test runs and the development of the processing of softwood-based biomass have resulted in a broad patent portfolio. In addition to this the company has acquired a profound knowledge of pre-treatment of these materials, which leads to high sugar yields and lignin suitable for various purposes.

We have developed a continuous fermentation process that today enables a process that is six times faster compared to standard fermentation. It also requires a fraction of the amount of yeast otherwise used. Furthermore the fermentation volume is also smaller than the conventional, which reduces equipment costs.

Sekab offers a process package license that can be implemented in pre-existing fermentation processes. The collaboration between Praj and Sekab makes it possible to merge a unique patent portfolio and many years of experience in continuous processing with plant design and construction.

As such, it feels extremely exciting to take the next step with Praj to realize the CelluAPP technology platform for coniferous residues.

Together we can help and tackle the climate challenges!