Project Polestar 0 aims to produce a completely climate-neutral car by eliminating all greenhouse gas emissions from raw material extraction, material production, product manufacturing, and life cycle. The project’s goal is to change how cars are made. The approach involves collaborations throughout the value chain, and we are one of the partners helping Polestar map out greenhouse gases and identify challenges. The project also opens opportunities for us to expand our product portfolio to new chemicals from ethanol.

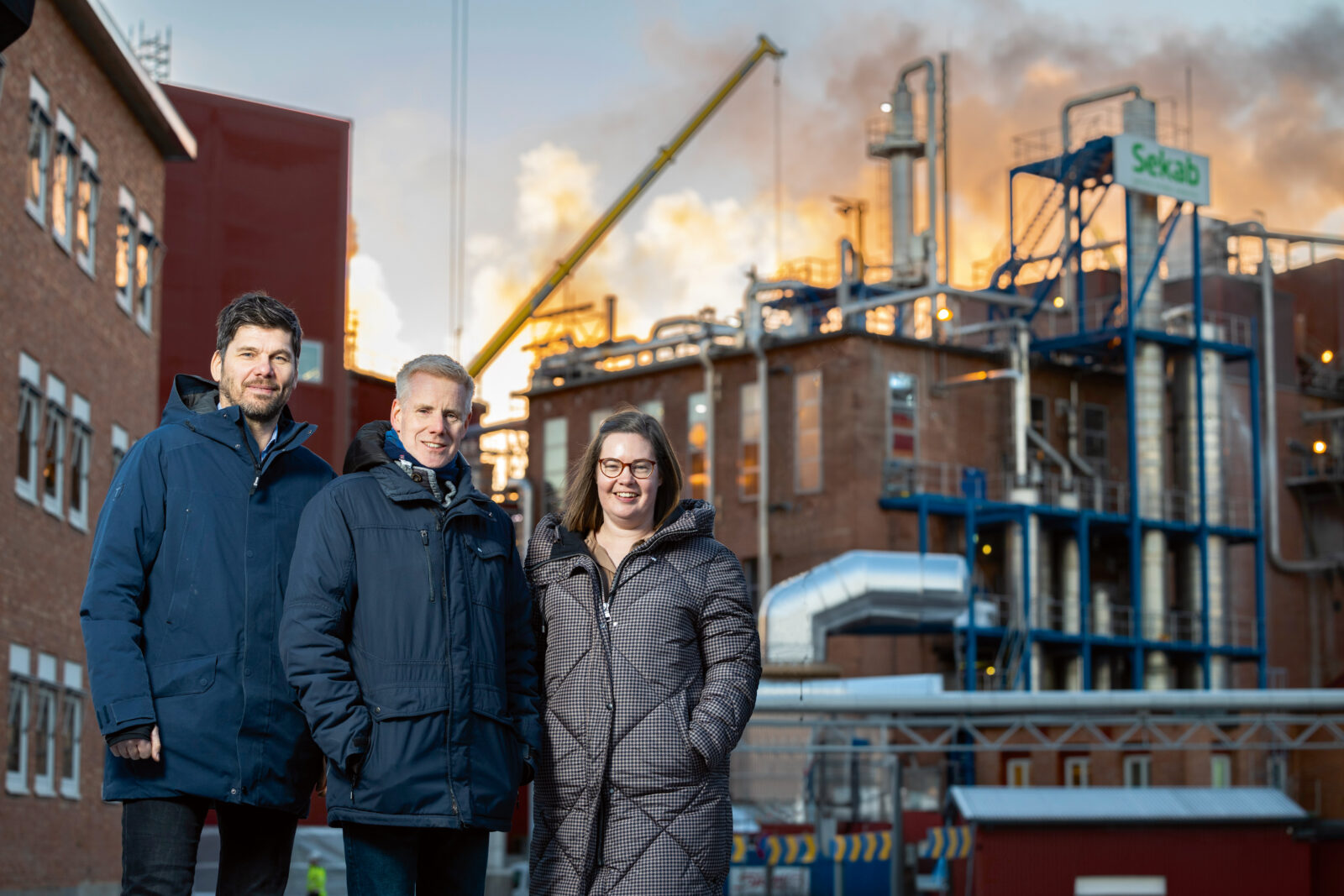

During a visit to us at Sekab in December 2022, Tomas Holst, Project Manager of Polestar 0, and Rachel Holland, Research Manager of Polestar, explained why they chose us as a partner and what we will achieve together going forward.

– Most companies have a plan to reduce carbon emissions, but their timeline is different from ours, says Tomas Holst. Polestar 0 is trying to solve the unsolved problems here and now. We must rethink where we extract raw materials from. If we continue to emit this level of greenhouse gases, we are heading for disaster. We have so little time left and need to take big steps quickly. The idea is to change how cars are made and commercialize this – not just create some exhibition samples.

– We don’t work from the top down with our value chain, but from the bottom up. We don’t take accepted facts for granted and don’t accept that they are made into a standard. In this project, the starting point is not to use fossil raw materials. Then we must find new ways and look at the problem from different angles. That’s why we have started a collaboration with Sekab.

– Name a component where chemicals from Sekab do not play a role! They are in plastics, adhesives, paints, tires, and alcohol fluids, to name a few. The connection between sawdust and our products is not as distant as one might think.

– You might think it’s unique that we’re going down to the chemical level, but it’s about hierarchy and power over the situation. Manufacturing companies and product suppliers don’t always want us to know all the details. They also often pass the problems on. The emissions and costs are always someone else’s fault. Sekab has a core understanding of what we can change and what we should focus on. They work with innovative biomaterials, and we speak the same language. All our questions are welcome here, and by getting the answers, we remove the excuse for the producers, says Tomas Holst

– I was impressed that Sekab accepted the challenge right from the start. The deep knowledge of chemicals and the long history of producing them with the forest as a source makes me very happy. Seeing and experiencing it on-site has been both different and captivating, he continues

Rachel Holland takes over:

– I think Sekab seems different because they are investing so much in this. When an engineer tackles a challenge and knows that change is possible, it awakens something. It sheds light on a chain that was previously almost only cost-driven. Where things come from has not been enough on the agenda. You can take the same molecule, like ethanol, and choose whether you want it fossil or not. We have to stop choosing fossil when the same building blocks are available as biobased.

– Polestar 0 is really important. We need to be brave, challenging, and open in collaboration – that also applies to ourselves. Only by sharing our problems can we solve them. Transparency is easier in a relationship. That’s why we’ve made this a joint project where we’re working towards the same goal, says Holland.

When asked where in the car we will find chemicals from Sekab, Tomas Holst responds:

– Name a component where chemicals from Sekab do not play a role! They are in plastics, adhesives, paints, tires, and alcohol fluids, to name a few. The connection between sawdust and our products is not as distant as one might think.

– This year’s collaboration has had two main ingredients. One is to map greenhouse gases and the other is to create an order basis for managers. We identify the root of the problem and find the chemical reactions. Then we either work around the problems or solve them, he says.

– The automotive industry is used to being cost-effective. We are forcing development to move quickly and scale up things. This way, we ensure the infrastructure for cost-effectiveness. The price is super important. We need zero greenhouse gas impact for a competitive price, so that no excuses are valid anymore. We know that it is possible to enter large-scale, green ethanol production. Now we also need to prove that it can be done at a competitive price and build momentum.

– We will end 2022 with more technical knowledge about where greenhouse gases come from and how they are linked to more parts of the car. Next year, we will figure out the supply chain that will take us to the goal. In fact, if everyone works hard on their small part and makes small changes, it will make a big difference together, concludes Tomas Holst