Current feasibility study

Current feasibility study

With the increasing demand for green chemicals, we see the opportunity to contribute to climate change adaptation by commercialising our technology. We are currently investigating the conditions required to build a production facility in Sweden that makes green chemicals from residual products from the forest.

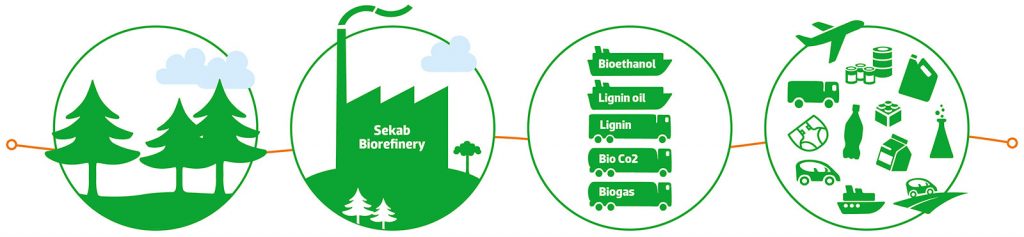

Sekab has developed a unique technology called CelluAPP. It takes residual products from the forest, such as sawdust, and processes them into green raw materials such as forest sugar, ethanol and lignin. They in turn can become products that contribute to climate change adaptation: from biofuels to asphalt and medicines. The technology has been developed and tested by us in our demo facility and is now ready for large scale use.

Sekab has the technology that can be part of the solution to the challenges of climate change. The transition to sustainable solutions must go faster and the time is right for us to take our responsibility and investigate the possibility of letting our technology contribute more.

The Swedish forest is a fantastic resource that can be utilised more if we make use of the residual products. Swedish technology can contribute to reduced emissions and to green jobs in Sweden.

By taking the first step ourselves, we can pave the way for more and similar investments based on our unique technology. Our collaboration with Praj continues to demonstrate the value of this technology in a global market and our own production facility will strengthen the possibilities that our technology will make a difference.

We have been working with the CelluAPP technology for a long time. We are carrying out a feasibility study with the aim of establishing a production facility in Sweden that utilises the technology.

Among other things, the feasibility study will investigate the financing of this facility. Since this project is in line with the European priority to invest in technology that contributes to climate change adaptation, we have submitted an application to the European Innovation Fund.

The feasibility study is also looking into the issue of location. The first choice is that the facility should be adjacent to the bioeconomic cluster in Örnsköldsvik, however the availability of raw materials and the possibilities regarding suitable land and environmental permits must be examined in the feasibility study before a decision can be made.

The feasibility study will be completed in the autumn of 2022 and thereafter an investment decision can be made.

With the strict and distinct climate goals that are now in place, the transition must go faster. There is an increasing demand for green products and the potential to make more out of the forest is great. Sekab has developed a technology that takes residual products from the forest such as sawdust and converts them into green chemical products. It is now time for this ground-breaking technology to be used on a large scale. We are therefore actively exploring the possibilities of building a production facility in Sweden based on this technology. It is our responsibility to contribute to a more sustainable world.

Monica Normark – Chief Technology Officer

Demand is expected to increase, mainly in the transport sector but also for further production of biochemicals.

Potential customers: fuel manufacturers and the chemical industry

This versatile product can be used, for example, instead of oil as a binder in asphalt. The forecast for the global market is a 265 percent growth by 2025.

Potential customers: construction sector, asphalt producers, oil and gas producers and the pulp and paper industry

Can be used as a sustainable marine fuel. Sekab and Vertoro are already collaborating to develop bio-based crude oil that can be used as bio-fuel.

Potential customers: maritime actors and the chemical industry

Demand is expected to increase by 20 percent per year given political decisions on tax reliefs.

Potential customers: transportation sector, mainly shipping and heavy traffic

Carbon dioxide is expensive to transport and more Swedish manufacturers are required to cover the growing need from the food industry and the process industry.

Potential customers: actors in several large industry sectors, for example chemistry and food

The feasibility study is run by an experienced team with expertise in technology as well as economics, law, business and marketing.

Dr. Monica Normark, CTO Sekab Group

Monica Normark is leading the feasibility study as CTO of the Sekab Group. The feasibility study has its own company, Sekab Forest Technology AB, where Monica is CEO.

Monica has a doctorate in chemistry and has cutting-edge expertise in pretreatment and enzymatic saccharification of lignocellulose. with extensive experience from the paper industry. She has worked on several industrial projects at European level and has a large network of contacts in the bioeconomic sector.

Bertil Westman, CFO and Law

Bertil Westman has over 35 years of experience in the manufacturing industry, from paper to construction to chemistry. He has held several roles within the Sekab Group, including head of purchasing, logistics and finance. In the feasibility study, he is responsible for financing, finance and law.

Dr. Adnan Cavka, responsible for research and development

Adnan Cavka has worked for ten years with research and industrial development, both in Sweden and globally in both China and the USA. He has a doctorate in technical chemistry and has cutting-edge expertise in microbiology and fermentation. In the project, his role is to identify and refine business opportunities, linked to applied research. He is responsible for, collaboration with the academy, business and institutes, the IP portfolio and for monitoring the latest research.

Dr. Tino Lassmann, process technology development manager

Tino Lassmann has a decade of experience in simulation, model development and optimizing industrial processes, primarily in the pharmaceutical industry. He has previously driven EU-funded projects in the field. In the feasibility study, Tino is responsible for scaling up the CelluAPP technology from the demo to the production facility.

Ylwa Alwarsdotter, Marketing Manager

Ylwa Alwarsdotter has several decades of experience from leading positions in the chemical and paper industries. Her focus has been innovation and the market. In the feasibility study, Ylwa is responsible for sales and contracts with end customers.

Robert Nordin, Purchasing Manager

Robert Nordin has extensive experience in industry purchasing and logistics. His knowledge in business planning and management will be important for the project. In the feasibility study, he is responsible for purchasing, mainly from suppliers of raw materials.

Karin Hägglund, Production Manager

Karin Hägglund is currently the production manager of the demo facility and will in the feasibility study continue in that role when the technology is scaled up. Karin is a chemical engineer by training with experience from the paper industry. She has extensive experience of biorefinery technology from working with the development of Sekab’s technology platform for many years.

The team from Sekab is complemented by experts from AFRY. AFRY is an international company in technology, design and consulting with a strong focus on sustainability and digitalisation. In a collective approach to the bioindustry, AFRY supports customers in paper & pulp, chemistry, bio-based solutions and biorefining, which we see makes them a valuable partner who with their wide expertise can provide resources and an outside perspective for us to succeed together to ensure effective implementation in the best possible way. AFRY also has a wide expertise through its 16,000 employees worldwide, and we also see an advantage in a strong local presence as the company has been active in Örnsköldsvik for almost 40 years.

AFRY contributes to this project with three top competencies:

Christer Götesson, project manager

Christer Götesson has extensive experience of leading projects from start-up and assessment of business sense to implementation and operational management. In the feasibility study, he is the project manager.

Jan Iggström, Technical Project Manager

Jan Iggström has extensive experience of leading industrial projects from feasibility studies to implementation projects. As a technical project manager, Jan is responsible, among other things, for leading and quality assuring the technical part of the feasibility study.

Patrik Svensson, permit manager

Patrik Svensson has held leading roles in quality assurance and licensing at Domsjö Fabriker, Mondi Dynäs Väja and Örnsköldsvik municipality. In the feasibility study, he is responsible for permit testing and contacts with relevant authorities to ensure effective implementation.